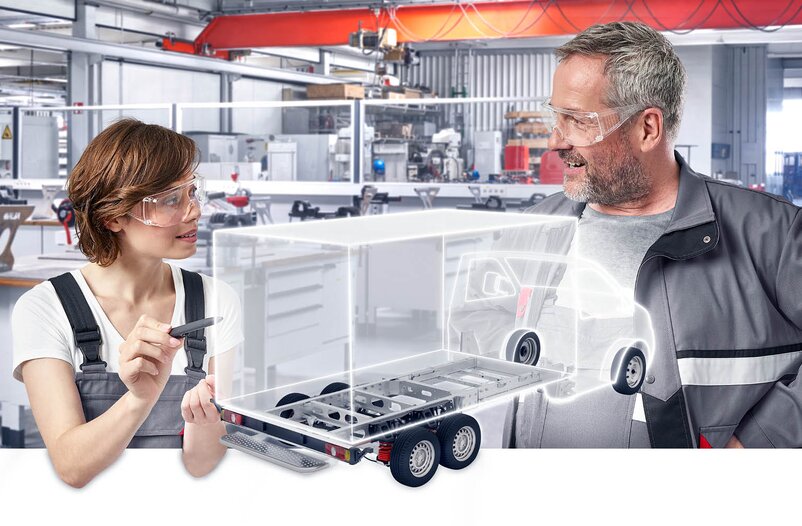

Vehicle Technology

AL-KO Vehicle Technology

for greater driving safety, comfort and joy

Welcome

We are a global technology group and a business unit of DexKo Global. With high-quality chassis and suspension components for trailers, leisure and commercial vehicles, and construction and agricultural vehicles, we represent the best in functionality, maximum comfort as well as innovations to ensure greater driving safety.