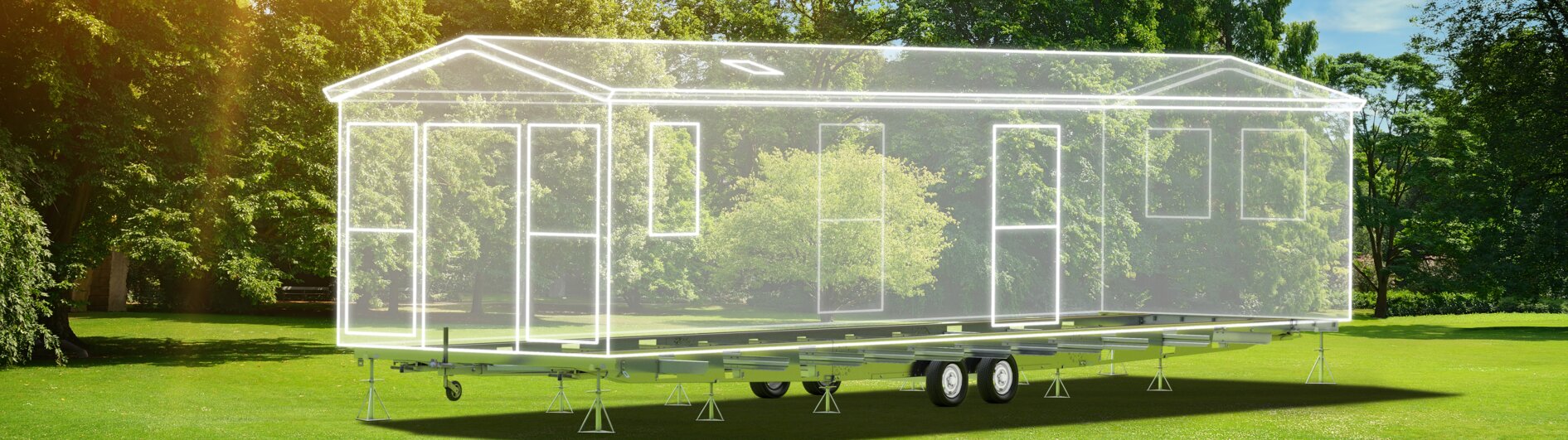

Vehicle Technology

Protech ECO Range

The self-assembly solution for holiday homes

Since 1959, we have established a reputation for quality and innovation in chassis manufacturing for the Holiday Home industry. Our Eco-Protech chassis, featuring a fully hot-dipped galvanised C5 coating, is designed to perform exceptionally well in high-salinity and coastal areas.

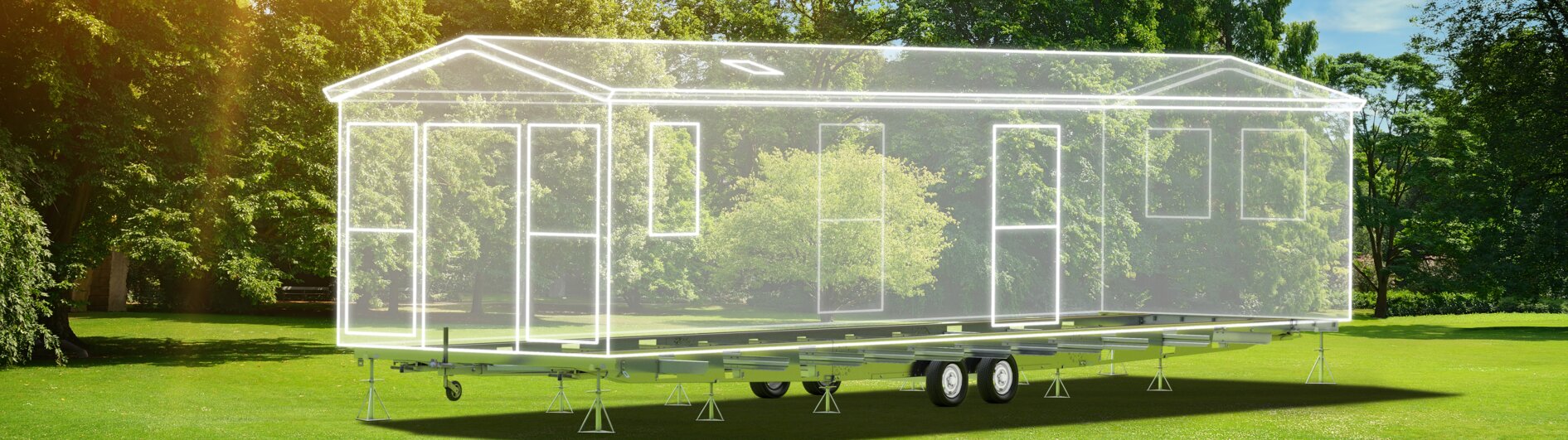

Cost Savings and Environmental Impact

- Considerable Logistics Savings: By opting for our self-assemble chassis, you can enjoy significant savings from reduced transport logistics. With 25 chassis fitting on a single delivery compared to only 5 fully assembled chassis, the cost-effectiveness is clear.

- Reduced Carbon Emissions: With fewer deliveries required due to compact packaging, you can reduce carbon emissions by a considerable amount, contributing to a more sustainable future.

Self-Assembly Efficiency

- Quick Assembly Time: Our self-assemble chassis can be put together in just 2 man-hours with 2 untrained individuals, equating to one hour per person. With trained staff and equipment, assembly time can be further reduced to approximately 30 minutes.

- Minimal Manpower Required: Only 2 untrained individuals are needed for assembly, making it a straightforward and efficient process.

With a commitment to strength, durability, and efficiency, our chassis deliver quality solutions and lasting value for clients across the industry.